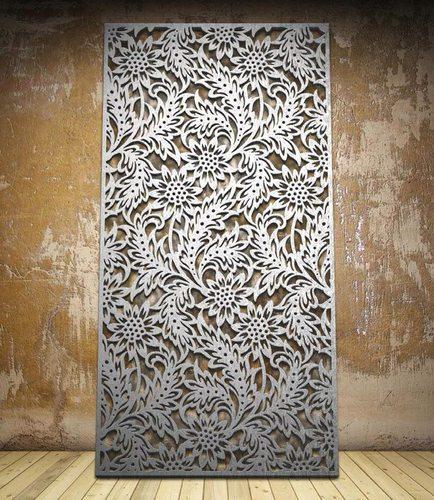

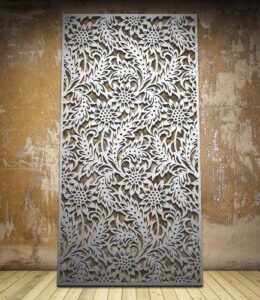

İstanbul Lazer Kesim Modelleri

İstanbul lazer kesim modelleri ve lazer kesim görsel çeşitlerinden bazılarını inceleyebilirsiniz

Lazer Kesim Ölçüleri

İstanbul lazer kesim yukarıdaki resim gibi 1 mt ye 2 mt ebatındaki laser kesimler genellikle tercih edilen ebatlardır. Elbette farklı ebatlarda bahçe duvarınız için veya başka amaçlı kullanılabilir laser kesimi yapmak mümkündür.Panel veya ferforje gibi kullanılacak lazer siyah sac kesim plakalarının tasarımı ve modellemeleri tarafımızca yapılmaktadır. Farklı şekillerde lazer plaka kesim yapmak isterseniz autocad formatında çizim göndermeniz gerekmektedir. İstanbul lazer galvaniz kesim fiyatlarını müşteri temsilcilerimize danışabilirsiniz.

Lazer Kesim Fiyat Hesaplama

Lazer cnc Kesim fiyat hesaplaması için öncelikle cnc lazer çelik kesim yapılacak malzemenin teknik çizimlerine ihtiyaç vardır. teknik çizim olmaksızın cnc lazer metal kesim fiyat çalışması yapılamamaktadır. İstanbul lazer kesim ile eğer elinizde cnc lazer sac kesim için teknik çizim mevcut ise tarafımıza iletmeniz halinde hemen fiyat çalışması yapılarak size gönderilecektir.

İSTANBUL LAZER KESİM MODELLERİ

Günümüzde lazer kesim makineleri, küçük ve büyük şirketlere paslanmaz, karbon çeliği, galvanizli ve hatta alüminyum malzemeler gibi lazerle kesilebilen metalleri kolayca işleyebilmektedir. Sonuç olarak şirketler, son derece karmaşık metal parçaları, prototipleri ve özelleştirilmiş parçaları düşük maliyetli ve verimli bir şekilde lazerle kesmek için harika bir fırsata sahiptirler:

– paslanmaz çelik

– yumuşak çelik

– alüminyum

– pirinç

– bakır

– ince sac

– <5mm için üstün hız

– işletme maliyeti verimliliği

– daha fazla güvenilirlik

– daha uzun hizmet ömrü

İstanbul Metal Laser Kesim

İstanbul Lazer kesim , malzemeyi özel şekillere ve tasarımlara kesmek için odaklanmış, yüksek güçlü bir lazer ışını kullanan bir imalat işlemidir. Bu işlem metal, plastik, ahşap, değerli taş, cam ve kağıt dahil olmak üzere çok çeşitli malzemeler için uygundur ve özel tasarlanmış takımlara ihtiyaç duymadan hassas, karmaşık ve karmaşık parçalar üretebilir.

Füzyon kesimi, oksidasyon kesimi ve çizme dahil olmak üzere çeşitli farklı lazer metal kesim türleri vardır. Her İstanbul lazer kesim çelik kesim işlemi, mekanik kesim ve su jeti kesim gibi diğer geleneksel kesim işlemlerinden daha hassas, doğruluk ve yüksek kaliteli kenar yüzeyleri olan ve genellikle daha az malzeme kirliliği, fiziksel hasar ve atık içeren parçalar üretebilir. Bununla birlikte, İstanbul lazer kesim , daha geleneksel kesme işlemlerine göre bazı avantajlar gösterse de, yansıtıcı malzeme veya ikincil işleme ve ince talaş işleme gerektiren malzeme kesmek gibi bazı imalat uygulamaları sorunlu olabilir. Belirli bir kesme uygulamasının talep ettiği gereksinimler ve spesifikasyonlar (örneğin, malzemeler ve özellikleri, enerji ve güç tüketimi sınırları, ikincil sonlandırma, vb.), Kullanım için en uygun kesme işleminin türünün belirlenmesine yardımcı olur.

Dudullu Lazer Kesim avantajları

Her kesme işleminin avantajları ve dezavantajları olsa da, bu makale lazer çelik kesim işlemine, lazer çelik kesim işleminin temellerine ve lazer çelik kesim makinesinin gerekli bileşenlerine ve mekaniğine odaklanmaktadır. Ek olarak, makale çeşitli lazer kesim yöntemlerini ve uygulamalarını, sürecin faydalarını ve sınırlamalarını ve lazer metal kesim ile diğer kesim işlemleri arasındaki karşılaştırmaları incelemektedir.

İstanbul lazer kesim Makinesi ve Süreci

Lazer sac kesim, metal ve metal olmayan malzemeler için uygun, temassız, termal bazlı bir imalat işlemidir. Lazer plaka kesim işleminin sorunsuz ve optimum kapasitede çalışması için, lazer metal kesim makinesinin konfigürasyonu ve ayarları, kesilen malzeme ve özellikleri ve kullanılan lazer ve yardımcı gaz türü gibi çeşitli faktörler dikkate alınmalıdır.

İstanbul lazer kesim Makine Bileşenleri ve Mekaniklerine Genel Bakış

Kesme aletleri ve güç tahrikli ekipman kullanan mekanik kesimin ve basınçlı su ve aşındırıcı malzeme kullanan su jeti kesiminin aksine, lazer özel kesim kesim, gravür ve işaretlemeler üretmek için bir lazer kesme makinesi kullanır. Lazer kesme makineleri modelden modele ve uygulamadan uygulamaya farklılık gösterirken, tipik kurulum bir lazer rezonatör düzeneği, aynalar ve lazer odaklama merceği, basınçlı gaz düzeneği ve bir nozul içeren bir lazer kesme kafası içerir. Temel lazer profil kesim işlemi aşağıdaki aşamaları içerir:

ışın üretimi

ışın odaklama

bölgesel ısıtma ve eritme

malzeme fırlatma

ışın hareketi

Her aşama lazer kesim işleminin ayrılmaz bir parçasıdır ve uygun şekilde yürütüldüğünde hassas bir kesim üretir.

Lazer Işın Üretimi

“Lazer” terimi, Uyarılmış Radyasyon Emisyonu ile LASER kısaltması veya Işık Amplifikasyonundan gelir. Esasen, bu kısaltma lazer üretiminin temel ilkelerini (stimülasyon ve amplifikasyon) özetler. Bu prensiplerin yanı sıra, lazer rezonatör, hem uzaysal hem de spektral olarak uyumlu (yani bir lazer ışını) yüksek yoğunluklu bir ışık demeti üretmek için spontan emisyon ve uyarılmış emisyon işlemlerini kullanır.

Spontan emisyon: Lazer rezonatör, elektronları flaş lambası veya elektrik arkı gibi harici bir enerji kaynağı tarafından uyarılan aktif bir lazer ortamı (örn., CO2, Nd: YAG, vb.) İçerir. Ortam enerjiyi alıp emdikçe, atomları kendiliğinden emisyon olarak bilinen bir süreç yaşar. Bu işlem sırasında, bir atom tarafından emilen enerji, atomun elektronlarının kısa bir süre daha yüksek bir enerji seviyesine atlamasına ve daha sonra yer durumuna geri dönmesine neden olur. Elektronların yer durumlarına döndüklerinde, atom bir ışık fotonu yayar.

Uyarılmış Emisyon: Spontan emisyonla üretilen fotonlar, iki ayna arasındaki lazer rezonatörünün boşluğunda bulunan ortam içinde hareket eder. Bir ayna, fotonların ortam içinde seyahat etmesini sağlamak için yansıtıcıdır, bu nedenle uyarılmış emisyonları yaymaya devam ederler ve diğer ayna, bazı fotonların kaçmasına izin vermek için kısmen geçirgendir. Uyarılmış emisyon, bir fotonun (yani, olay fotonunun) zaten daha yüksek bir enerji seviyesinde olan bir atomu uyardığı işlemdir. Bu etkileşim, uyarılan atomu, aynı sabit dalga boyuna sahip ikinci bir foton ya da gelen fotonla uyumlu ikinci bir foton yayarak yer durumuna düşmeye zorlar.