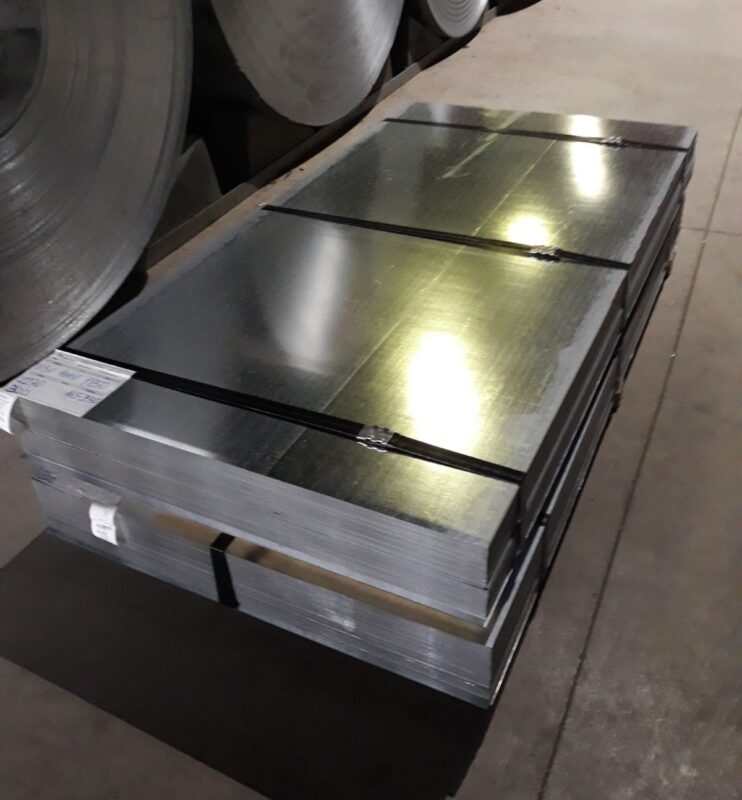

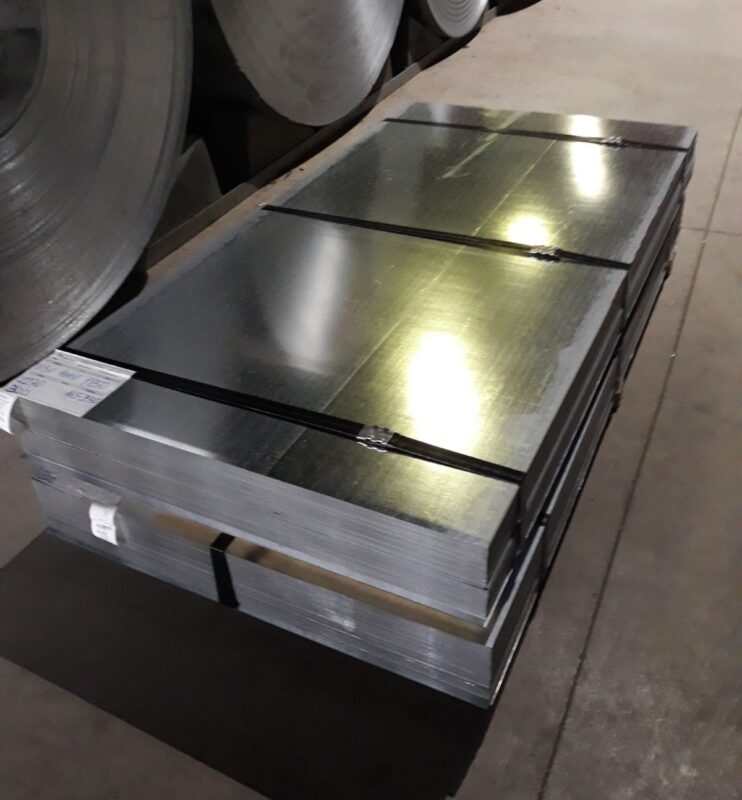

Rulo Sac Boy Kesim Hattı

Kesimini yapabildiğimiz Rulo Sac Türleri :

- Siyah Sac

- Dkp Sac

- Galvaniz Sac

- Alusi Sac

- Magnelis Sac

- Boyalı Sac

- Paslanmaz Sac

- Aluminyum Sac

Dünya Çelik Fiyatlarını Kolayca Takip Edin

En İyi Fiyat

En iyi Fiyat Alternatifleri

Çelik Fiyat Arşivi

Geçmiş Yıllar Çelik Fiyatları

Çelik Fiyat Karşılaştırma

Belirlediğiniz ürünlerde karşılaştırma yapabilme imkanı

ÜRÜNLERİMİZ – ÜRETİMLERİMİZ

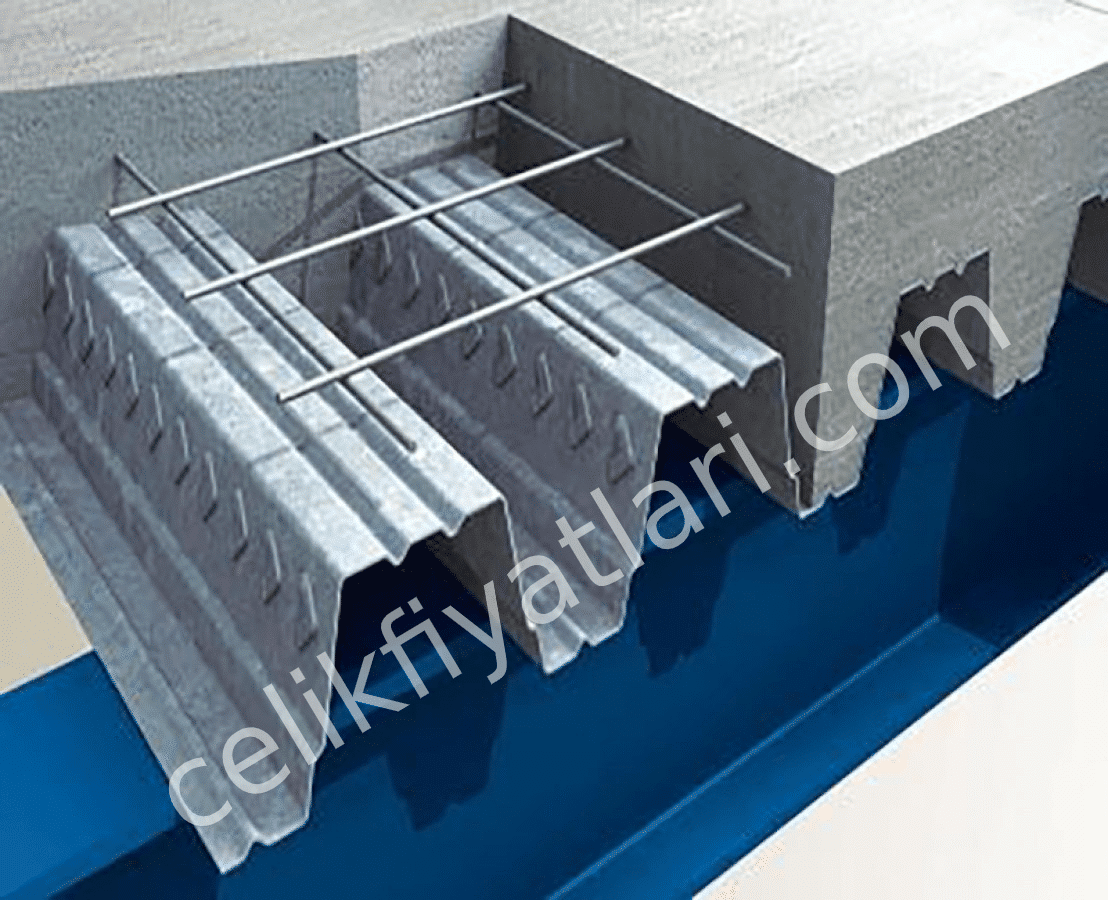

Galvanizli ve Boyalı Profiller

KENET SAC İMALATI

Kesimini yapabildiğimiz Rulo Sac Türleri :

Ayrıca Bant olarak satışlarımız mevcuttur.

İLETİŞİM

Kesimini yapabildiğimiz Rulo Sac Türleri :

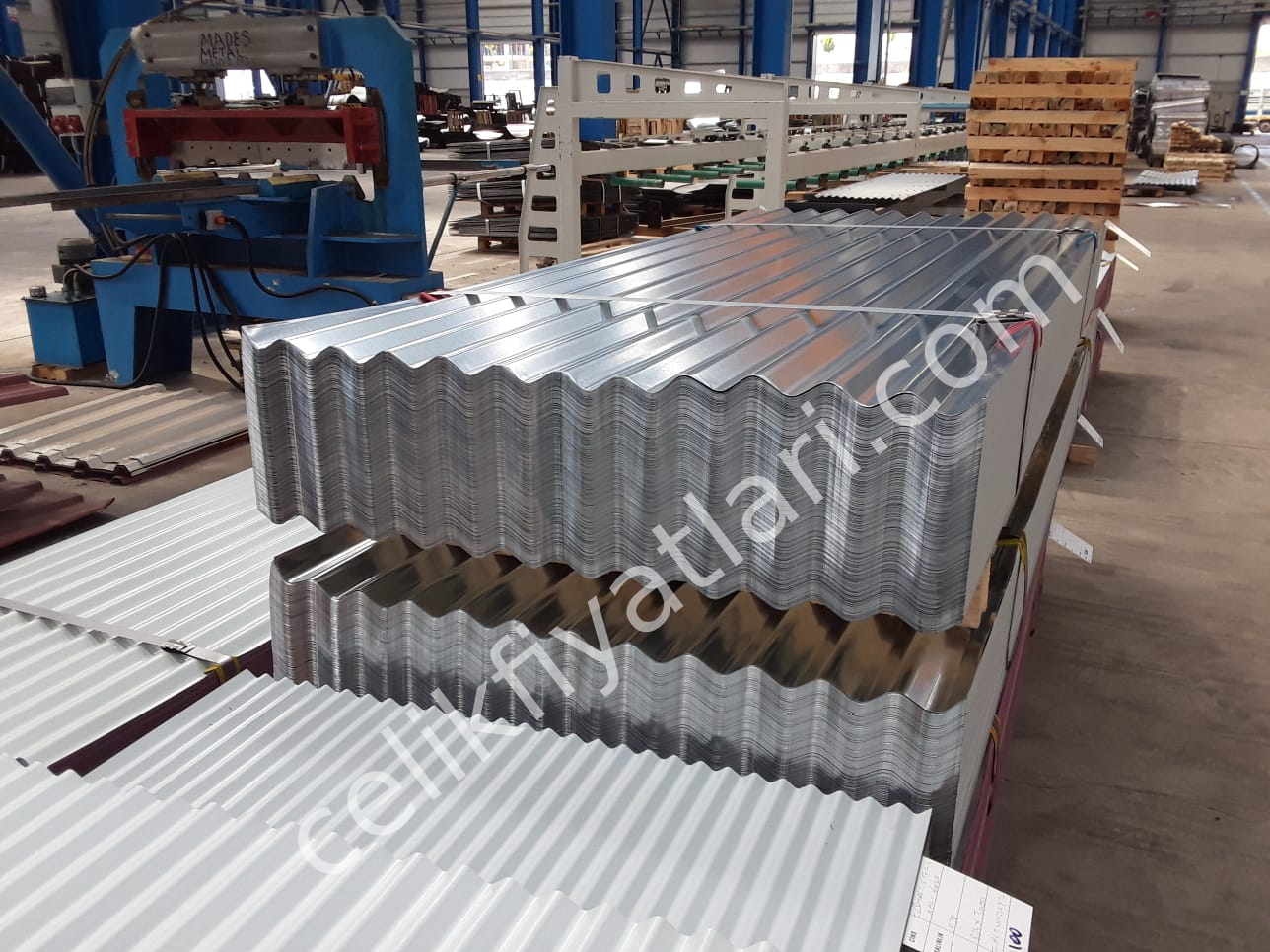

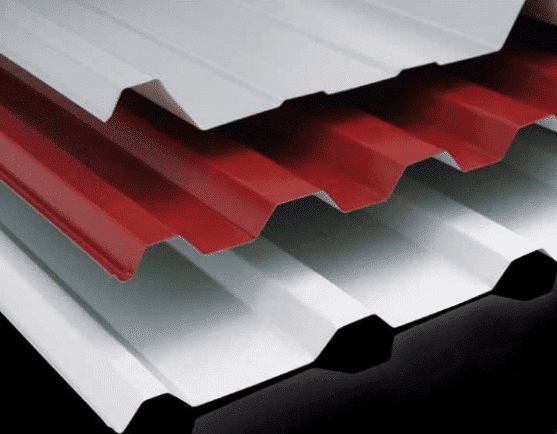

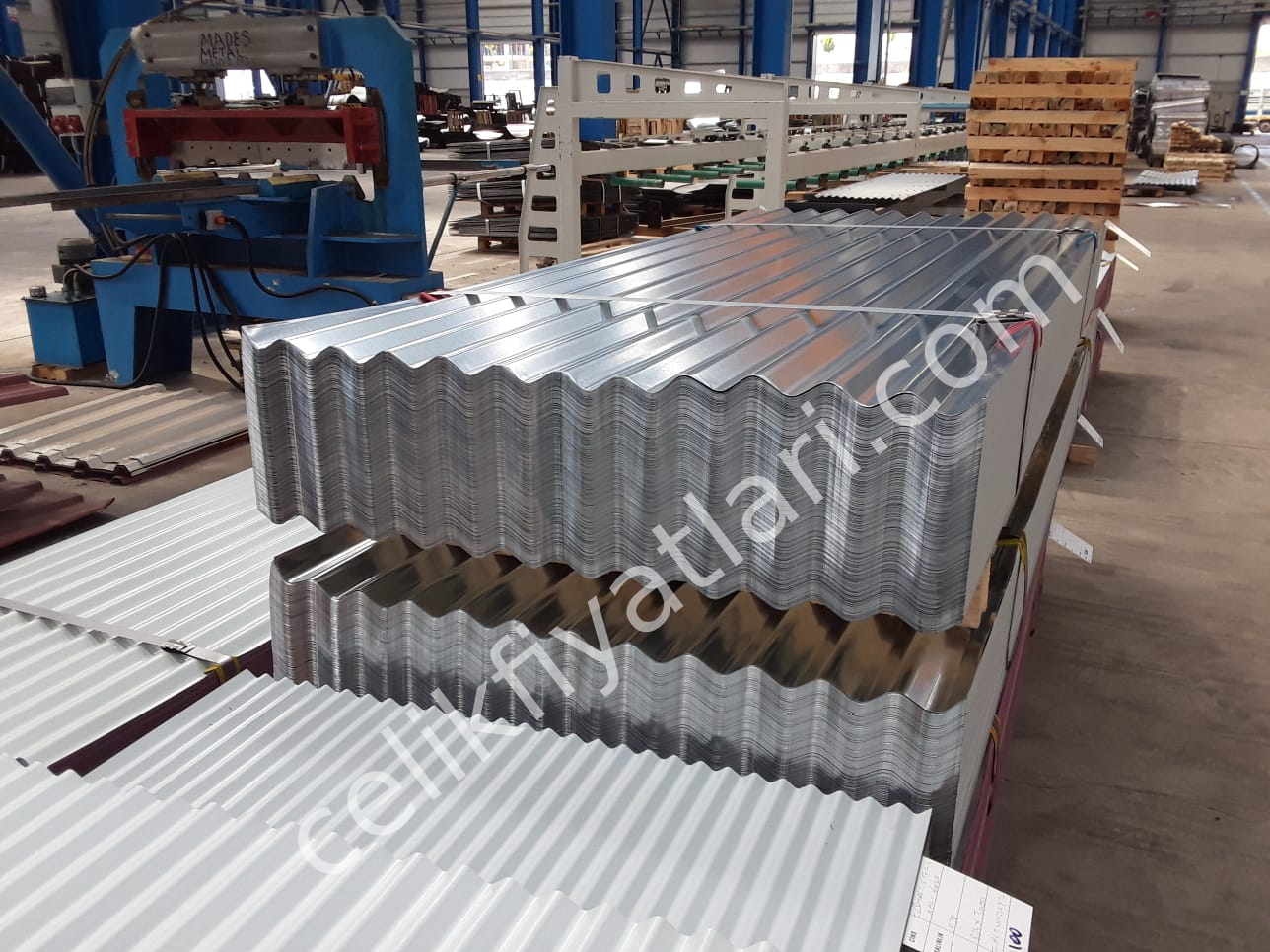

Oluklu Sac İmalatı

Galvaniz ve Boyalı Oluklu Sac İmalatı

15x15mm den 60x60mm ye kadar Galvaniz Profil Üretimi.

0,70mm den 2mm ye kadar kalınlıklarda Galvaniz Profil Üretimi

İLETİŞİM

CNC LAZER KESİM

PLAZMA KESİM

İHTİYAÇLARINIZA HIZLI VE EN İYİ FİYAT