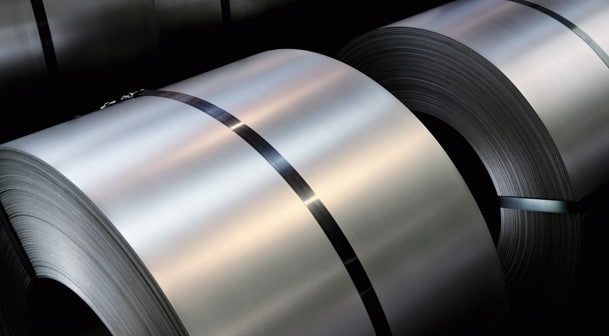

Rulo Sac Kesim

Kesim yapılacak rulo sac kesim farklı türlerde ve ebatlarda olabilirler. Farklı kalınlık ve türler için rulo sac kesme hatları da farklıdır. Rulo sac kesim hatları genellikle iki tiptir. İnce rulo sac kesme hattı ve kalın rulo sac kesme hattıdır.Rulo sacın kalınlığına göre rulo sac kesme fiyatları da değişmektedir.

İnce rulo sac kesim hattı

İnce rulo kesim hatları 0,20 mm ile 3 mm arasında rulo sac kesme kapasitesine sahiptir. Genellikle ince rulo sac kesim hatlarında paslanmaz rulo saclar, soğuk haddelenmiş rulo saclar, galvanizli rulo saclar, alüminyum rulo saclar ve kaplamalı rulo saclar kesilmektedir. Paslanmaz ve alüminyum kesme işlemi sonrasında iki sac arasına kağıt koymak ya da plaka sacları özel paketleme malzemeleri de kullanılmaktadır. Paslanmaz sacların yüzeyleri çok hassas olduğundan ayrı bir koruma kağıdı konulabilmektedir.

Teneke kesim hatları özel hassasiyet isteyen çok ince İnce rulo kesim için kurulmuş tesislerdir. teneke saclar 0,11 mm ile 0,22 mm arasındaki saclara denilmektedir. Teneke sacların bu kadar ince ve hassas olmasından dolayı paketleme işlemi de ayrı bir özen gerektirmektedir.

İnce rulo sac kesim hattı özellikleri :

- Rulo ağırlığı: max 17 ton

- Rulo iç çapı: min 508 – max 610 mm

- Rulo dış çapı: max 1800 mm

- Sac Kalınlığı: min 0,30 mm – max 2,5 mm

- Sac Genişliği: min 400 mm – max 1730 mm

- Kesme Uzunluğu: min 600 mm – max 6000 mm

- Rulo sac ütüleme Hızı: 100 m/dk.

- Kesme Tolerans: +- 0,5 mm

Yukarıda verilen bilgiler genel amaçlı olup rulo sac kesim fiyatları için teklif isteyiniz.

Kalın Rulo Sac Kesim Hattı

Kalın rulo sac boy kesim hatları genellikle sıcak haddelenmiş saclar için kurulmuş 1,5 mm ile 30 mm arasındaki rulo sacları kesmek için kurulmuş çelik servis merkezi makineleridir. Kalın rulo sac kesim makinelerinin ön merdaneleri özellikle sac ütülemeye uygun olarak yapılmaktadır.

Sac ütüleme ile sıcak haddelenmiş rulo saclar yüzey düzgünlüğü ve kırıksız olarak plaka sac haline getirilebilmektedirler. Sac ütüleme sıcak haddelenmiş rulo saclar için olması gereken bir makinedir. Kenar kesmesiz rulo saclarda ve kenar kesmeli rulo saclarda farketmeksizin sac ütüleme yapılabilmektedir. Rulo sac ütüleme sac yüzeyinde oluşabilecek kırıkları , dalgalanmaları ve yüzey bozukluklarını engelleyebilmektedir.

Kalın rulo boy kesim hattı özellikleri :

- Max Rulo ağırlığı: 25 ton

- Rulo iç çapı: min 600 mm – 800 mm

- Rulo dış çapı: max 1950 mm

- Sac Kalınlığı: min 2 mm – max 30 mm

- Sac Genişliği: min 750 mm – 2000 mm

- Kesme Uzunluğu: 12000 mm

- Rulo sac ütüleme Hızı: 50 m/dk.

Rulo sac kesim fiyatları işlenecek malzemeye göre değişmektedir.

Rulo sac kesimi ile her seferinde mükemmel kesimi elde edin!

Özelleştirilmiş imalat teknolojisindeki son gelişmelerden biri, kumaşları kesmek için lazerlerin kullanılmasıdır. Bu işleme genellikle lazer kesim denir. Kumaş kesiminde lazer kullanmanın birçok avantajı vardır. En önemli avantajı lazer kesim kenarının çok temiz olması ve yıpranmış kenarlarının olmamasıdır. Kumaş az atıkla hızlı ve kolay bir şekilde kesilebilir. Lazerler, kumaştaki desenleri kesmek için de kullanılabilir, bu da bitmiş ürünün daha fazla özelleştirilmesine olanak tanır.

Sac Kesme İşleminizi Basitleştirin

Kaliteli bir rulo sac kesim aleti için , haddeleme ve ütülü rulo sac kesici mükemmel bir seçenektir. Bu tip kesicinin kullanımı kolaydır ve sac kesme işleminizi hızlandırmanıza yardımcı olabilir. Ayrıca lazer ışını kullandığı için her seferinde temiz ve doğru uzunlukta kesimler üretir.

Rrulo sac kesme Sac, aluminyum, paslanmaz dahil olmak üzere çok çeşitli malzemelerle kullanım için mükemmeldir. Küçük rulo veya istenilen uzunlukta kesimler yapmak için de harikadır.

Rulo Sac kesim teknolojisi, malzemelerde hassas kesim yapmak isteyen işletmeler için popüler bir seçim haline geliyor. Geleneksel kesme yöntemlerinden farklı olarak Rulo Sac kesme, bozulma olmadan temiz bir kenar bırakır. Bunun nedeni, kesilen malzemeyi düzgün kesmesidir.

İşletmeniz için Rulo Sac kesim teknolojisini kullanmanın birçok faydası vardır. Birincisi, malzemenizin tam olarak sizin spesifikasyonlarınıza göre kesilmesini sağlayan çok hassas bir kesme yöntemidir. İkincisi, Rulo Sac kesim hızlı bir süreçtir, bu da ürünlerinizi müşterilerinize hızlı bir şekilde ulaştırabileceğiniz anlamına gelir. Son olarak Rulo Sac kesim, metal, sac, aluminyum gibi çeşitli malzemeler üzerinde kullanılabilen çok yönlü bir işlemdir.

Malzemelerinizde hassas bir kesim elde etmenin bir yolunu arıyorsanız, Rulo Sac kesim mükemmel bir çözümdür.